Screen printing is a decoration technique that’s been around for ages. Today, we use screen printing as the most economical way to print to apparel like T-shirts, hoodies, jerseys, and more when doing medium- to large-volume orders. For one or two colour designs, we have a screen print minimum of just 12 pieces with the same artwork. If your design is multi-coloured, the minimum order quantity may vary. In some cases, for no minimum or low volume orders one of our digital printing methods will yield a better price.

We can work with any form of electronic artwork. For screen printing we prefer vector artwork; however, if your artwork is not vector based, our art department can make the appropriate conversions to be able to screen print it. With silk screen printing you have to consider that your artwork will always need to be optimized so we can literally print it through a screen!

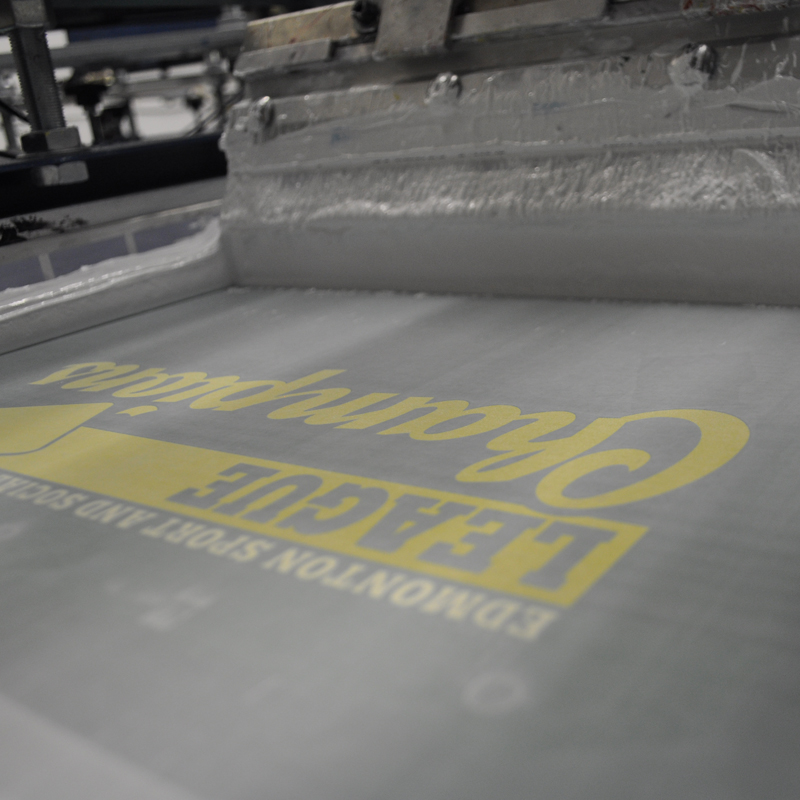

Screen printing process

There are a number of steps in the screen printing process:

- Artwork optimization

- Outputting films

- Screen exposures

- Press set up

- Printing

- Print curing and garment fixation

Types of screen printing

On top of that, there are a number of ways to screen print too:

- Spot printing

- Four colour process

- Simulated spot process

- Screen printed transfers

And that’s just to name a few. Depending on the garment we’re printing, on we might use a plastisol ink or water-based inks.

Screen printing “special effects”

There are also a bunch of cool “specialty” and “special effects” things we can do when we’re screening, such as:

- Puff prints

- Discharge prints

- Reflective ink

- Metallic inks

- Glow in the dark

- and so much more!

The process can be complicated, but we’re here to help, and if you want to learn about it, we’ll do our best to educate you at the same time.

Let’s get started! View our custom apparel or promotional products and start designing, or contact us for assistance!